What We Can Do For You

Northland Chemical delivers complete integrated wastewater treatment solutions, custom tailored wastewater treatment chemicals, as well as expertise in operating wastewater treatment equipment that your plant may need to solve its specific wastewater treatment challenges. We manufacture and distribute water treatment chemicals. Our focus is on industrial and municipal applications for which our customers can benefit from our extensive application expertise.

For Industrial Applications:

1. Collaborating with clients to assess their wastewater treatment needs.

2. Assisting clients with the development of a sewer bylaw compliance plan and helping those same clients to obtain compliance plan approval from their city or municipality.

Northland Chemical’s chemical treatment programs are capable of reducing the following contaminants to permissible levels:

Biological Oxygen Demand (BOD) is a chemical procedure for determining the amount of dissolved oxygen needed by aerobic biological organisms in a body of water to break down organic material present in a given water sample at a certain temperature over a specific time period. It is not a precise quantitative test, although it is widely used as an indication of the quality of water. BOD can be used as a gauge of the effectiveness of wastewater treatment plants.

Chemical Oxygen Demand (COD) test is commonly used to indirectly measure the amount of organic compounds in water. Most applications of COD determine the amount of organic pollutants found in surface water (e.g., lakes and rivers), making COD a useful measure of water quality. It is expressed in milligrams per liter (mg/L), which indicates the mass of oxygen consumed per liter of solution. Older references may express the units as parts per million (ppm).

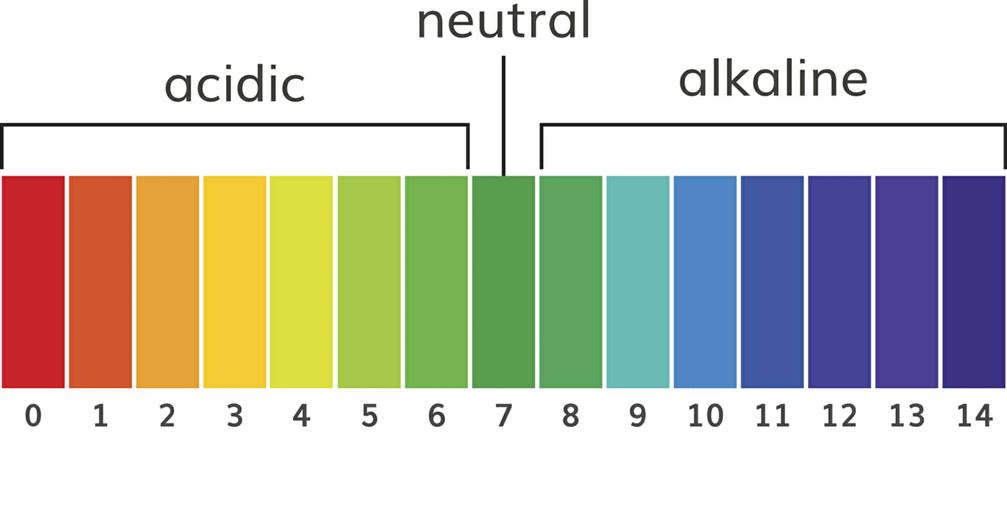

Acidity or alkalinity (pH) of wastewater affects both treatment and the environment. Low pH indicates increasing acidity, while high pH indicates increasing alkalinity (a pH of 7 is neutral). Many industrial wastewaters containing emulsified solids, oils, soaps, surfactants or dissolved metals require pH adjustment in order to precipitate (drop) out of solution prior to filtration or dewatering. Northland Chemicals can monitor and adjust pH levels for treatment or discharge purposes.

Fat, Oil, and Grease (FOG) from organic materials from animals, vegetables and petroleum can cause pollution in receiving environments. When large amounts of oils and greases are discharged to receiving waters from community systems, they increase BOD and they may float to the surface and harden, causing aesthetically unpleasing conditions. They can also cause foul odors. In some cases, too much oil and grease causes septic conditions by preventing oxygen from the atmosphere from reaching the water.

Metal hydroxides in the form of excessive levels of toxic heavy metals in wastewater can be hazardous to man, animals, and plants. By definition, a heavy metal has a specific gravity of about 5.0 or greater and is usually poisonous when present in your wastewater. The term heavy metal, however, is often broadly applied to include other potentially hazardous elements, even if they do not meet the strict chemical definition. Concentrations of metal hydroxides such as zinc, copper, nickel and chrome found in rinse water can result in contamination of the environment. Government authorities set the discharge parameters and companies generating heavy metal wastewater are responsible for complying with those disposal limits and regulations.

Heavy metals discharge levels including those for arsenic (As), cadmium (Cd), chromium (Cr), lead (Pb), nickel (Ni) and selenium (Se) are regulated by government authorities.

Total Suspended Solids (TSS) in wastewater can consist of organic and/or inorganic materials and organisms. The solids must be significantly reduced by separation methods or they run the risk of causing disease or detrimental environmental effects. Suspended solids in wastewater must be treated or they will clog or penetrate the filter media and reduce system effectiveness.

Total dissolved solids

Total dissolved solids (TDS) are any anions, cations, metals, minerals or salts found in wastewater. They can cause issues with aquatic life, irrigation and crops, and they can also seep into groundwater. TDS can be generated in wastewater from just about any industry.

Nitrates and phosphates

If large amounts of nitrates and/or phosphates are not removed from wastewater and these nutrients are discharged into local environments, they can lead to an increase in BOD and extensive weed growth, algae, and phytoplankton. This can further lead to eutrophication, the deoxygenation in a body of water, killing the organisms and potentially leading to hypoxia or environmental dead zones.

Pathogens

Pathogens are bacteria, viruses, fungi or any other microorganisms that can be present in wastewater, that can lead to all kinds of health issues. These include acute sickness, severe digestive problems or even death. When domestic or industrial wastewater contains these harmful pathogens and is not treated, it can spread illnesses and diseases such as cholera, dysentery, salmonellosis, hepatitis A, botulism, and giardiasis, to name a few.

Synthetic chemicals

When pesticides and other chemicals are used/made in the manufacturing process, they can be transmitted to humans and the environment through wastewater, causing damage to the environment and human health. Some common chemicals found in wastewater include diethylstilbestrol, dioxin, PCBs, DDT and other pesticides. These “endocrine disruptors” can block hormones in the body and affect the functions that these hormones control.

4. Performing extensive lab tests on samples taken from clients and formulating custom chemical solutions tailored to the specific requirements of each customer.

Northland Chemical pursues a philosophy of continuous improvement, both in the formulation of treatment chemicals as well as in the application of those products. Our success is reflected in the significant cost reductions enjoyed by our customers over time.

5. Ensuring that wastewater treatment equipment is suitable for the application and is operated in a way that produces the desired results. Northland Chemical can operate in-plant wastewater treatment systems on behalf of our customers when desired by them.

6. Working with and training plant personnel to ensure that our treatment chemicals are being optimally applied and their equipment is set up to produce the best possible results.

7. Providing ongoing support of our customers through regular in-plant visits.

Northland Chemical’s business philosophy is far more than simply supplying treatment chemicals. Our clients’ operational needs are our highest priority. Our skilled technical team members work directly with your staff to make sure that every product we supply is delivered on time and used to its full potential and peak efficiency. This approach results in the optimal performance of your facility’s processes as well as its full compliance with municipal discharge norms.

For Municipal Drinking Water Applications:

Northland Chemical does not generally supply bulk coagulants such as Alum to drinking water plants. Rather, it specializes in solving challenging problems such as extending filter bed run times and dewatering filter backwash slurries. In the case of the former, many drinking water plants seek to extend run times help to reduce the amount of produced water used to backwash filters. Run time extensions effectively increase capacity and reduce costs. Northland Chemical has developed proven chemistry and methodologies to achieve these objectives via the dramatic increase in filter bed run times. In cases where drinking water plants seek to dewater backwash slurries, Northland Chemical can surely assist. Backwash slurries can be tricky to dewater. Northland Chemical troubleshoots processes as well as chemistry to optimize dewatering results.

For Municipal Wastewater Applications:

Municipal wastewater treatment plants can benefit from Northland Chemical’s expertise in sludge thickening and dewatering. Northland has significant experience in both areas. Application expertise extends to the following equipment:

Sludge Thickening Technologies

- Rotating Drum Thickeners

- Dissolved Air Flotation units

- Gravity Bed Filters

- Settling Systems

- Screw Presses

Sludge Dewatering Technologies

- Decanters

- Belt Presses

- Rotary Presses

- Screw Presses

- V-Fold Folding Belt Presses

Northland Chemical does not simply select and supply polymers that produce the driest cakes. Rather, it focuses on meeting the specific needs of each municipal wastewater treatment plant, taking the capabilities and limitations of each into account. Sometimes the driest sludge is too dry for conveyance by pumps. On other occasions, the polymer that produces the driest cake has a narrow operating dosage range, making it difficult to operate plants without excess operator intervention. If this sounds familiar to your municipal wastewater treatment plant, Northland Chemical can provide assistance.