Sugar Processing

Northland Chemical represents Lenzing Filtration of Austria in the North American sugar industry. In order to produce white crystalline sugar out of sugar beets or sugar cane, a variety of process steps are required. Along with extraction, purification, evaporation and crystallization, filtration represents one of the key processes in sugar manufacturing.

Filtration is required for sugar streams like thin juice, thick juice and molasses to produce high quality sugar in an economical way. Furthermore, filtration is an essential process step in the area of water filtration for purification of condensate, wash water or cooling water.

Lenzing Filtration has been successful in the field of filtration for more than forty years and delivers remarkable benefits to the sugar industry with its uniquely designed OptiFil® and CakeFil® automatic backwashing filters.

The OptiFil® can filter down to 3-5 microns without filter aid, provides continuous filtration even during the backwash process and eliminates the use of filter bags. Applications include thin juice polishing, thick juice filtration, standard liquor filtration, molasses polishing, re-melt purification, as well as water filtration.

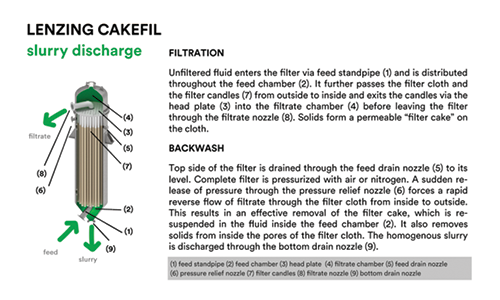

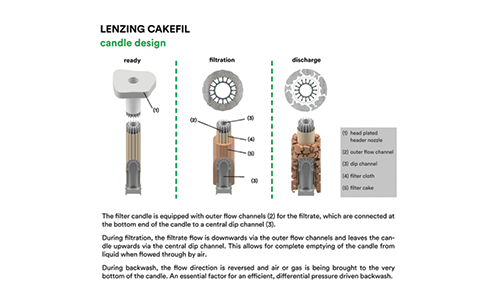

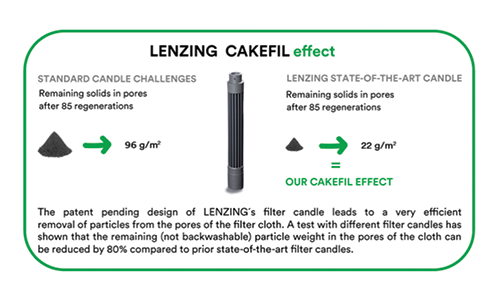

The CakeFil® tubular pressure (candle) filter has a uniquely designed patent pending candle and process design which combine to provide industry best cloth cleaning efficiency as well as the highest operational ROI. It’s THE game changer in solids cake and alternatively precoat filtration. In essence, the CakeFil® filter is a fully automatic version of manual labor intensive plate and frame filter presses and pressure leaf filters. There is no need to open and close the CakeFil® filter for months, perhaps years! Applications include thin juice thickening/filtration, thick juice recoat filtration and molasses precoat filtration.

Northland Chemical also represents Englo Inc. of West Virginia in the North American sugar industry. Englo manufactures two very different product lines that are both applicable to sugar production facilities and refineries. One of these product lines is wet dust extractor systems, the other flume water filters for use by beet sugar refineries.

Englo’s wet dust extractor systems are a safer technology to use than baghouse type dust collectors for handling fugitive combustible dust encountered in sugar facilities. These systems are designed to prevent combustible dust explosions. They have a lower initial acquisition cost as well as a lower operating cost when compared with baghouse type dust collectors.

Englo’s flume water filters for use by beet sugar refineries for solid debris removal. Beet debris and leaf fibers captured from wash water are directed onto a filter belt and are then separated with particle size removal flexibility. In some facilities, beet debris containing sugar is recycled. Return on investment from an Englo Optimal brand flume water filter can sometimes be achieved in one single sugar campaign.