Processing Systems Knowledge Base

After Northland Chemical’s treatment chemicals have successfully separated contaminants from the wastewater, the contaminants must still be physically removed from the wastewater, leaving clear water that can be disposed to sewer in full compliance with municipal discharge norms. This contaminant removal process is accomplished via the use of mechanical processing equipment.

Northland Chemical has aligned itself with a select few extremely competent manufacturers of specialty process equipment. We can evaluate wastewaters to be treated and make recommendations relating to the appropriate process equipment to be used. We will refer our clients directly to these process equipment manufacturers and will support communication exchanges.

Northland Chemical has experience in the operation of a broad variety of process equipment. We provide ongoing support for the entire wastewater treatment process. We have developed excellent troubleshooting skills and we are capable of helping our customers to resolve their process equipment operation and troubleshooting issues.

Specialty process equipment can be divided into a number of categories. These include Physical Chemical (Phys-Chem) Wastewater Treatment Systems such as clay systems that use Northland Chemical’s clay chemical formulations, as well as sludge dewatering systems. Northland Chemical can direct its clients to industry leading manufacturing partners for these processing systems. Generally speaking, Northland Chemical technical representatives can lend their expertise in all areas related to Filtration, Flotation, Settling and Sludge Dewatering.

Clay Systems

Batch and continuous flow wastewater treatment systems use Northland Chemical chemically adjusted clay. A batch treatment system provides complete control over the treatment process and is typically suitable for small to mid-sized volume waste streams. Batch processing allows for adjustments to the treatment process, an advantage in the case of the existence of variable or concentrated wastewater steams.

A batch treatment system generally incorporates a treatment tank, agitators, chemical feed, pumping system, solids separation and gravity bed filter. This system may be configured to use dry or liquid chemistry from Northland Chemical.

Continuous flow wastewater treatment systems process incoming wastewater on an ongoing basis. As water flows through the system, it passes through various treatment stages. A steady flow of untreated wastewater is transferred into the system, while an equal volume of treated effluent continuously exits the equipment. A non-variable (consistent) waste stream is most suitable for a continuous system. High wastewater throughput may be achievable.

Continuous processing requires treatment tanks, agitation, chemical feed, pumping system, solids separation and filtration. This system may be configured to use Northland Chemical’s dry or liquid chemistry.

Filtration

Filtration is generally useful for smaller waste streams or for waste streams where flotation or settling is not possible.

Common filtration systems include:

- Plate and Frame Filter Presses

- Gravity Bed Filters

- Bag or Cartridge Type Filters

- Rotary Vacuum Drum Filters

- Other Vacuum or Pressure Filters

The decision as to which specific filtration system should be selected is based upon the filtering characteristics of the wastewater, the dryness objectives for the sludge, as well as upon relative costs (OPEX vs CAPEX).

Flotation

Flotation systems include:

- Dissolved Air Flotation

- Induced Air Flotation

- Palin Flotation

- Wemco Flotation

Flotation is the method of choice for most industries which have organic contaminants in their wastewater. The food processing industry is one of these. Organic contaminants have specific gravities which are close to 1.0 and are therefore readily floatable.

With dissolved and induced air flotation, the air supply system is critical to the process. It is not uncommon for some floatation systems to have mechanical problems related to their air supply systems. These problems result in sub-optimal process performance.

Northland Chemical has extensive experience with the operation of flotation systems. We routinely help our customers improve the performance of their floatation systems.

Settling Systems

Settling systems include those listed below. Our technical representatives have regular exposure to:

- Lamella Clarifiers

- Graver Clarifiers

- Sedimentation Tanks

- Actiflow Clarifiers

- Circular Clarifiers (Center Well Feed, Peripheral Feed and Upflow)

- Solids Contact Clarifiers

Settling systems work well with solids that are significantly heavier than water. The metal plating industry routinely operates settling systems for this reason. Settling systems are also the system of choice for large scale projects for which lengthy retention times are desired. The challenge facing clarifier operators is to minimize the carryover of solids into the discharged water.

Northland Chemical can help minimize carryover in these systems by optimizing both chemical treatment as well as system operating procedures. Northland Chemical has notably developed methods of operation that significantly increase clarifier capacities.

Sludge Dewatering Systems

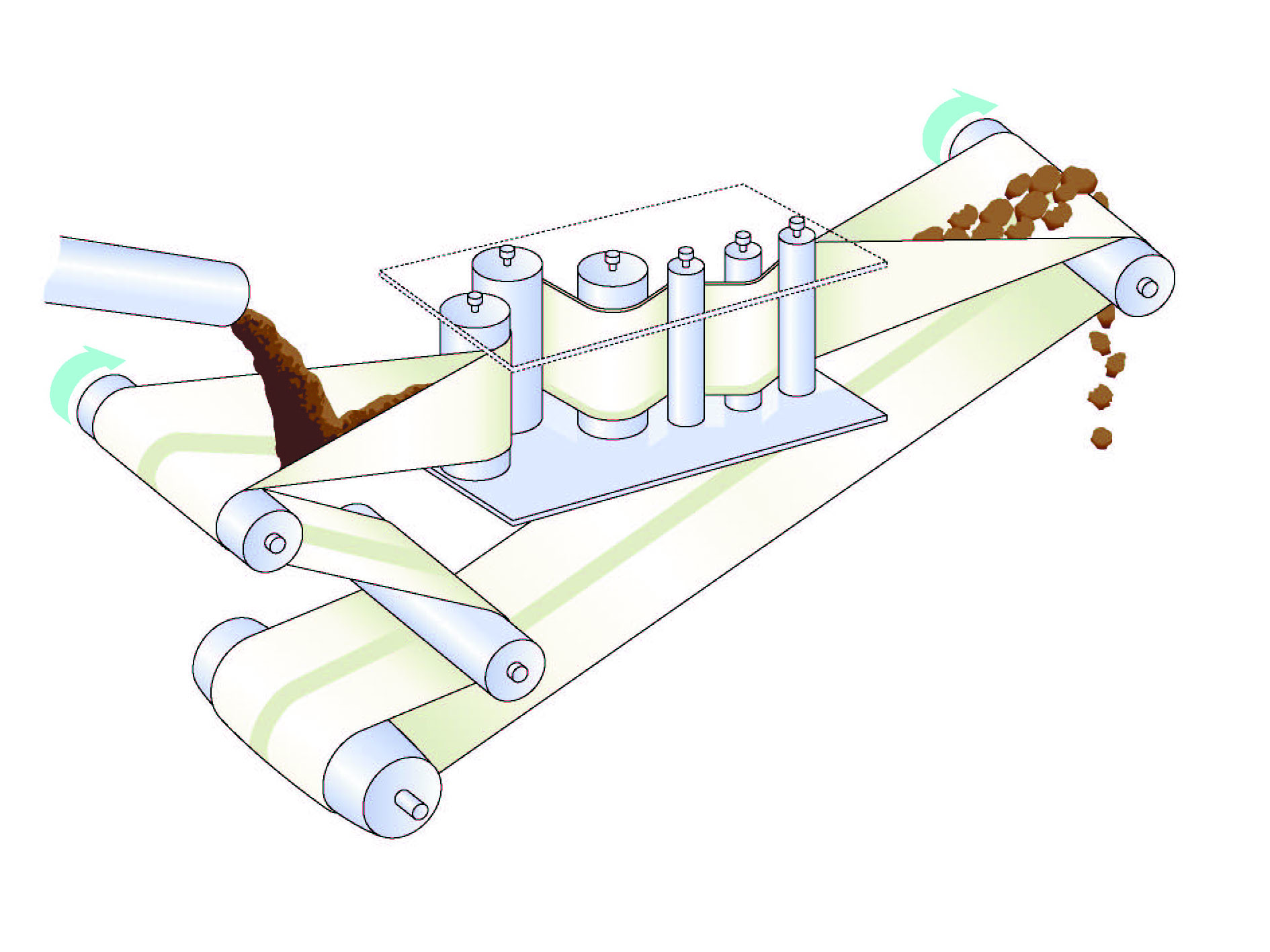

Sludge dewatering systems such as folding belt presses dewater sludge as the belt folds along the centre to form a V-shaped cavity. Sludge is squeezed as it passes around a series of vertical rollers where pressure and shear form a filter cake. Folding belt presses are forgiving of variations in feed composition that can upset other types of dewatering devices.